Hydraulic and electrical lines all pass through a rotating axis while the slewing ring carries the loads. You have fewer brackets, less cabling, and a cleaner layout that’s easier to install and maintain.

Key Components and Their Roles

- Multiport Rotary Union: This is the fluid pathway through the rotating joint. It routes hydraulic oil across a 360° rotating part without twisting hoses. Port count, passage size, and seal materials are matched to your pressures, while the internal seal stack keeps leaks in check and the rotor running true.

- Electrical Slip Ring: This is the electrical bridge. The slip ring transfers electrical power, control signals, and data across a rotating interface. It maintains continuous 360° rotation while delivering stable power and low-noise signals, so you can run sensors, controls, encoders, CAN, or Ethernet without cable wrap-up.

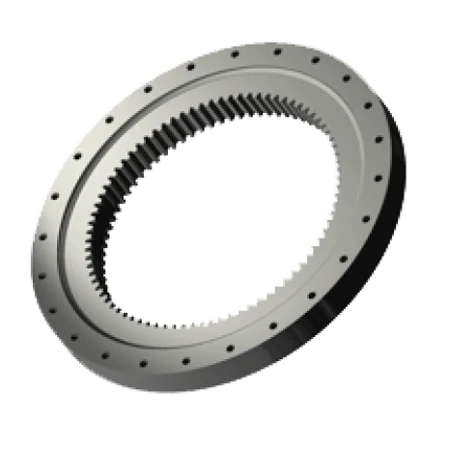

- Slewing Ring Bearing: This is the load-carrying foundation. It takes the axial, radial, and moment loads of the rotating structure and provides precise mounting and alignment for the rotary union and slip ring. Optional internal or external gearing lets you drive the rotation directly with a pinion or slewing motor. Commonly used in heavy-duty rotating machinery such as cranes, wind turbines, and robotics.

Benefits of Integrating All Three Components

- Continuous 360° rotation with power, signal, and fluid transfer: Move electrical power, control/data signals, and multiple media through the same rotating axis with no twisted hoses or tangled wiring. The result is uninterrupted operation for automation, robotics, and heavy equipment where downtime is expensive.

- Compact, space-saving design: Combining the rotary union and slip ring within the slewing-ring assembly shrinks the footprint and cleans up routing. Engineers can design tighter turrets and tables without separate paths for power and fluid.

- Higher reliability with less maintenance: Advanced seal stacks in the rotary union prevent leaks at working pressure and speed, while eliminating hose twist and cable flex reduces wear. Components last longer and service intervals stretch out.

Typical Industrial Applications

- Heavy equipment & cranes: Pairing a slewing ring with a rotary union and slip ring lets cranes, excavators, and grapples rotate freely while delivering hydraulic power for lifting and precise electrical signals for sensors, lights, and controls.

- Wind turbines: Slip rings carry power and control signals to the nacelle, while rotary unions support hydraulic blade-pitch systems and lubrication, enabling smooth pitch control.

- Robotics & automation: Perfect for robot arms and rotary indexers that need continuous rotation while delivering data.

- Machine tools & CNC: Multiport unions feed coolant and lube through the spindle, as slip rings transmit encoder feedback, spindle power, and temperature data for stable, repeatable machining.

- Packaging & food processing: For rotary filling or capping machines, the integrated solution creates continuous operation without hose tangling or cable fatigue.

- Medical & imaging: CT and other imaging systems benefit from continuous high-speed rotation with uninterrupted data and power transfer for crisp images and dependable uptime.

How Each Component Fits a Crane

- Slewing ring bearing – the rotational backbone: Allows the crane superstructure (upper works) to rotate a full 360° while supporting heavy axial loads from the boom. It delivers smooth, controlled slewing so the operator can position the load accurately and safely.

- Multiport rotary union – the fluid-power gateway: The rotary union transfers multiple hydraulic circuits from the stationary base into the rotating upper. Cranes often run several circuits at once, one for the hoist, another for the slew drive, and others for outriggers, jibs, or auxiliary tools. A multiport design keeps those flows separated and steady.

- Electrical slip ring – the power and control link: The slip ring maintains uninterrupted electrical power and data between the lower structure and the rotating deck. It feeds the cab, lights, cameras, and sensors while carrying signals for load-moment indicators, limit switches, interlocks, and high-speed telemetry for remote monitoring of fleet systems.

Benefits for Crane Design and Operation

- True 360° continuous rotation: With the bearing, rotary union, and slip ring working together, the crane can swing endlessly in either direction without stopping to unwind hoses or cables.

- Compact, robust center module that’s easy to service: Nesting the rotary union and slip ring inside the slewing ring’s inner diameter creates a single, tidy hub. Designers gain a lower center of gravity, cleaner hydraulic and electrical routing, and fewer exposed parts that can snag or corrode.

- Multi-circuit hydraulic capability: One rotary union can handle high-pressure flow for the main hoist, a low-pressure return for cooling, and independent lines for attachments.

- Reliable, long-life performance: Advanced sealing resists leaks under pressure and rotation, whether on dusty jobsites or offshore decks.

- Safety and efficiency gains: Stable power and clean signal paths keep overload limiters, interlocks, and emergency-stop circuits online. Fewer loose hoses and cables mean fewer failure points and fewer operator errors.

Crane Types and Typical Applications

- Tower cranes — Continuous slewing without cable twist, smooth hoist and trolley control, reliable power to the operator cabin.

- Mobile (truck-mounted) cranes — A compact center module lowers weight and height, improving transport and speeding setup.

- Crawler cranes — Supports high flow for heavy hoisting and boom control while powering sensors and monitoring systems.

- Offshore/marine cranes — Corrosion-resistant sealing and continuous power/fluid transfer suited to saltwater conditions.

- Loader/knuckle-boom cranes — Smooth actuation across multiple boom sections with dependable power and controls through rotation.