Wire Brush Slip Rings

At United Equipment Accessories (UEA), we have developed slip rings with wire brushes. This innovation offers greater design flexibility in both power and signal transfers. Employing wire brushes in slip rings introduces numerous advantages, notably enhancing power and signal quality across various applications. These wire brushes achieve a 75.6% reduction in resistance compared to their carbon counterparts, operating at a minimal 15-25 milli-ohms. This allows power circuits to handle up to 20 amps at 240 volts.

Benefits of Wire Brush Slip Rings

- 75.6% reduced resistance compared to existing carbon brushes. 15-25 milli-ohms

- Power circuits rated to 20 AMP at 240 volts

- Designed to meet customer specifications from 0.09” to 23” for power/signal requirements, including Ethernet (using filter module)

- IP65 to IP69 designs available

- Can replace standard products without any modifications

- Vertical height advantage for more compact designs

- Maintenance-free, long life

- No carbon dust

Durable Performance with Enhanced Data Transmission and Signal Clarity

Wire Brush Technologies are engineered for exceptional durability, addressing common challenges like wear and frequent maintenance seen in traditional slip rings. By significantly extending the lifespan of these components, this advanced design helps businesses reduce upkeep expenses and downtime, providing a reliable and efficient solution for long-term use.

In applications where precise data transmission is a priority—such as defense and surveillance—maintaining signal clarity is essential. The innovative contact design of Wire Brush Technologies provides minimal electrical interference and consistent signal performance, enabling smooth and accurate operations, even under demanding conditions.

Compact, Customizable, and Efficient

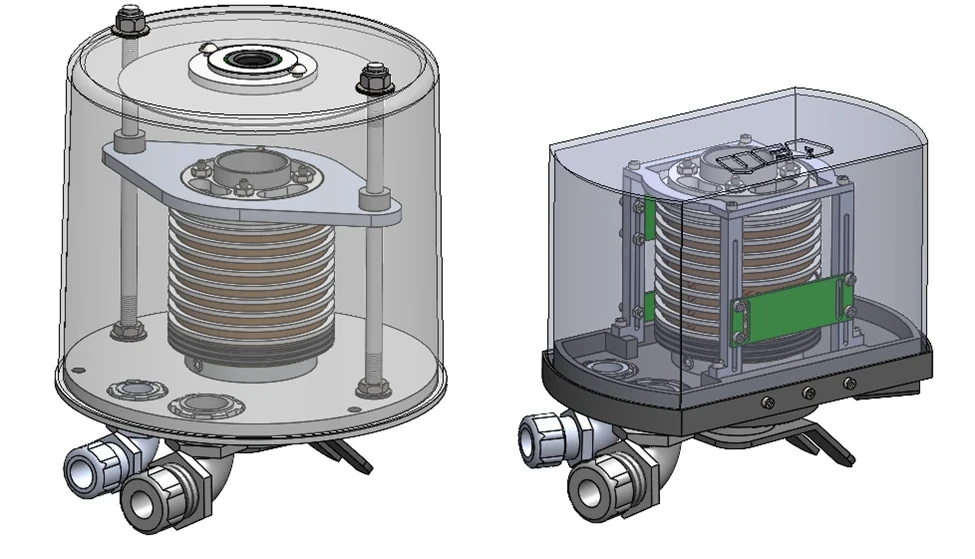

UEA Wire brush slip rings have a distinct vertical height advantage compared to carbon brush slip rings. This means that wire brush slip rings have a more compact design vertically, allowing for installations in spaces where height is a limiting factor.

Moreover, our wire brush slip rings can be tailor-made to meet specific customer requirements, ranging from 0.09″ to 23″ in power/signal requirement, inclusive of Ethernet through the use of a filter module. The design, protected from IP 65 to IP 69, is not only resilient but also adaptable, capable of replacing standard products without necessitating any modifications.

Enhanced efficiency and cost-effectiveness – beyond technological merits, the compact design of our wire brush slip rings offers economic benefits, facilitating up to 20% cost savings for customers by reducing shipping and overall inventory storage space needs.

In terms of packaging, our innovative design accommodates more units per box and reduces the overall weight of the slip ring by 35%.

Shown is an example of the size reduction possible when wire brushes are used verses the conventional carbon brush design.

We provide technical expertise, and responsive customer service from design to installation, including the integration of advanced solutions like Wire Brush Slip Rings for optimal performance and reliability.