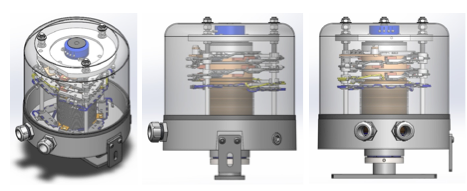

A new version of United Equipment’s S15D series slip ring has completed our engineering design process. Due to overall height restrictions, this slip ring takes advantage of our “ultra-compact” circuits. On our standard slip rings, we use a two-post brush design with the brushes evenly spaced at 180 degrees. Our “ultra-compact” slip ring design uses three brush posts evenly spaced around the center core. This allows us to get more brushes packed inside every valuable inch of space.

This particular crane application required 3 power circuits and 40 circuits for control and communication. At the top of the assembly, position switches are used to notify the crane operator when the boom is over the front and when the boom is over the rear. A potentiometer is also used to indicate the slew angle so the crane operator knows how much weight they can lift.

At the bottom of the assembly, a custom mounting tube flange is used to attach to the stationary portion of our customer’s hydraulic swivel. For the outer retention method, a specialized slotted bracket is used to house a pin, which allows the slip ring to rotate with the boom of the crane.

Custom wire harnesses are supplied with this slip ring, which completes the bolt-on, plug-in design of our slip rings.