United Equipment Accessories (UEA) designs and manufactures custom slip rings. One design specification that we ask about is the temperature range at which the slip ring will operate. In this blog, we will show what design considerations can be made depending on the temperature requirements.

High-Temperature Applications

Slip rings used in hot environments up to 350°F (176°C), such as oil and gas downhole drilling equipment, need to have materials that can be rated to withstand high temperatures. High-temperature insulators and core caps can be used to ensure the integrity of the core stays intact. Along with utilizing high-temperature insulators, UEA also designs slip ring with several types of high-temperature brushes. These additions to the core assembly are explicitly designed for high temperature and high shock environments.

The use of high-temperature plastics and assembly materials ensures the slip ring maintains industry-leading performance. High-temperature plastics are typically used in high-temperature applications and are rated up to 350°F. Along with high-temperature plastics, solder rated for high-temperature applications is also used. High temperature-rated solder has strong bond strength, excellent corrosion and oxidation resistance, and excellent thermal and electrical transfer at the braze joint.

Cold Temperature Applications

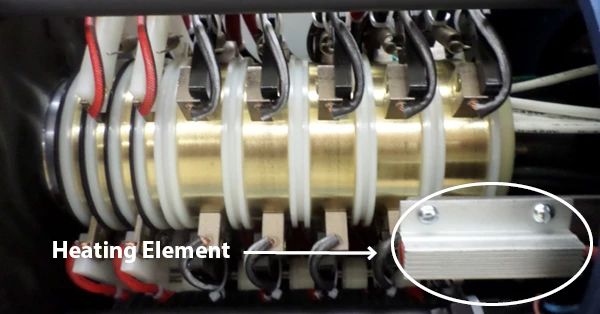

Slip rings might be found on forestry equipment operating in winter conditions or a crane in the cold Arctic temperatures. A heating element can help a slip ring operate at -49°F (-45°C). The heating element is used to prevent condensation and ensures a minimum operating temperature in small enclosures. Along with the heating element, a thermostat can maintain the temperature within the slip ring. The heating element emits radiant heat while the thermostat detects the temperature and will disable the heating element once the temperature reaches a determined level.

Using suitable materials and components for the operating temperature is critical to maintaining the proper function of the slip ring. Contact UEA today to design a slip ring for your operational parameters.