United Equipment Accessories (UEA) designs each slip ring to meet the unique demands of the application. One of the many custom specifications that UEA can accommodate is the addition of an air swivel to the slip ring. Adding an air swivel allows the customer to run an air hose on each end of the slip ring without worrying about the hose getting tangled during operation. This slip ring add-on has proven to be beneficial for the following applications: pallet wrappers, packaging machinery, machine shops, assembly lines, and applications in automation.

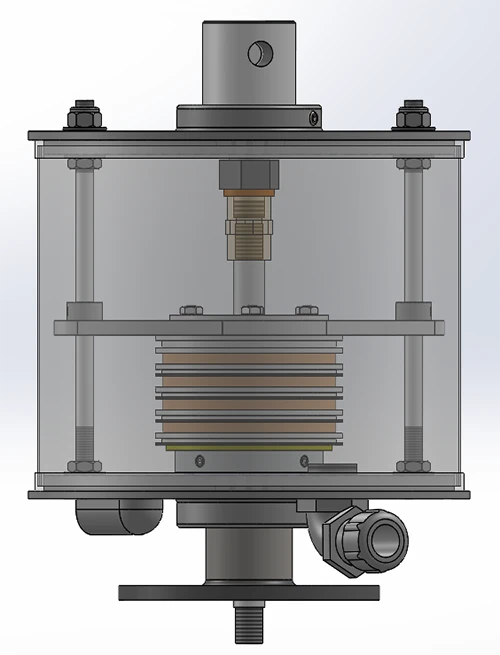

Most commonly, the slip ring with an air swivel is designed with a threaded steel pipe that runs through the center of the swivel from the bottom of the mounting tube out through the cover. In prewired slip rings, we build the portion of the center harness that passes through the slip ring around a plastic tube. This allows us to evenly spread out the wires in the center harness around the steel pipe during assembly.

The steel pipe is then attached to an air swivel above the top casting or cover. The air swivel is retained to the top casting or cover with set screws. Retaining the air swivel to the top casting or cover allows the air hose to turn freely with the slip ring. The air swivel can be configured in size as well as the number of ports, ranging from one to four ports. The air swivel is generally supplied with standard sizes of pipe thread for customer to attach their application’s air connections. The customer can determine how far the threaded steel pipe sticks out of each end of the slip ring to meet their application requirements.