Here in the Innovation and Technology department at UEA, we are constantly attempting to challenge the status quo of the slip ring manufacturing industry. One of the biggest challenges we face is how we can further downsize the footprint of our slip rings while increasing the capability. The recent developments of the UEA wire brush technology and employment of selective laser sintering 3d printing have allowed us to do just that.

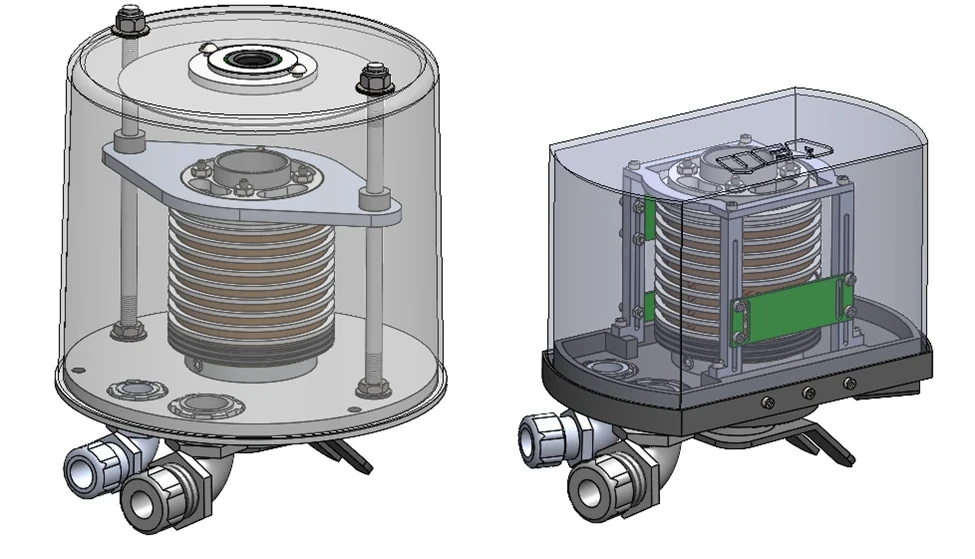

The wire brush has been in development for some time at UEA. Testing results have exceeded expectations for both power and signal circuits. Increased capacity is only one of the benefits gained by using wire brushes. Due to the compact nature of the design, the overall footprint of the slip ring can be greatly reduced. Shown below is an example of the size reduction possible when wire brushes are used as opposed to the conventional carbon brush design.

While size reduction is greatly appreciated by our customers, the slip ring geometry becomes inherently more complex. Machining these parts from aluminum or steel would be cost prohibitive, so we lean on our in-house SLS printing capabilities. SLS (selective laser sintering) is an additive manufacturing process where a thin layer of powder material is laid across a build chamber, and a laser from above melts and bonds the cross-sectional area of the part. This process repeats until the finished part is complete in a “cake” of powder material. The part is then extracted from the loose power surrounding it, and the power is reclaimed to be used for the next print. SLS affords many benefits over the more widely known FDM (fused deposition modeling) 3D printing method.

FDM printing requires that the printed part is supported from below so the material can cool and harden without the concern of drooping due to gravity. Since SLS parts are suspended in powder, there is no need for additional support, allowing for more complex geometry. UEA uses a glass fiber reinforced nylon material in all SLS prints. This results in mechanical properties that are nearly identical to injection molded Nylon GF30. Another benefit that is often overlooked when using the wire brush coupled with SLS printed parts, is the drastic weight reduction of the complete slip ring. The reduced weight makes shipping, handling, and assembly of the slip rings a much less arduous task.