When designing cable reels at United Equipment Accessories (UEA), one of our main focuses is always to ensure that the finished product will perform in the specified environment and application. Every UEA custom cable reel is designed to function within specific environmental parameters laid out by our customers. Corrosion is an important environmental concern that is addressed in our design process. Luckily, there are several design considerations that UEA utilizes to help combat corrosion.

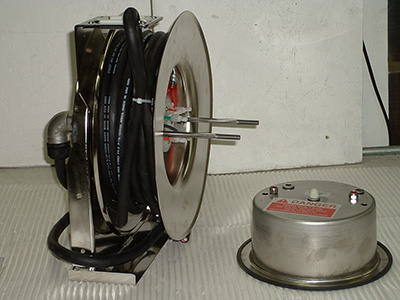

Both the exterior and interior parts of the cable reel need to be able to withstand a corrosive environment on their own. When designing a custom cable reel for a corrosive environment, we use a stainless-steel cable reel. When we design the slip ring for the cable reel, we make sure to either use stainless steel parts or coat slip ring parts, which are susceptible to corrosion, in Alodine. For example, on a recently designed cable reel for a corrosive environment, we used a stainless-steel cover, and we had both the core base and the base casting dipped in Alodine. Both parts were not stainless steel. Alodine acts as a primer for the paint and ensures that the slip ring parts would not rust or corrode.

In addition, we make sure to seal the product as well as possible. In order to do this, we use liquid tight connectors with sealing gaskets where the harnesses and cables exit both the slip ring and the cable reel. We also use cover seals to seal off where the cover and base casting meet, and shaft seals to seal off where the base casting and the cable reel meet. Another measure we take is to use stainless steel nylon lock nuts and sealing washers to hold the cover on the studs. All these items help to seal off any gaps in the slip ring that are attached to the cable reel.

Interested in learning more about how our custom cable reels can meet your application’s demands? Contact us for your cable reel solution today!