This article originally appeared in North American Clean Energy, July 15, 2017

-By Jesse Shearer

Engineering Manager

United Equipment Accessories, Inc.

When most people think of wind turbines, bigger components like motors and blades immediately come to mind. Smaller components, on the other hand, are often overlooked. However, it’s those small components that can make or break a system.

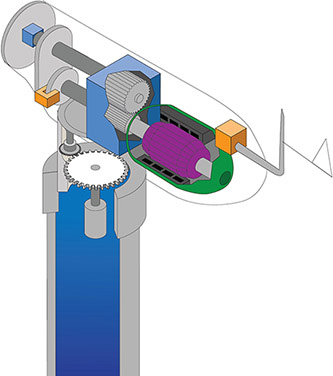

A perfect example is the slip ring assembly—also known as an electrical rotary union—for pitch control systems. The slip ring is tiny when compared to the whole wind turbine. But its impact can’t be ignored. If your slip ring malfunctions or has critical issues, the turbine shuts down.

So even though the slip ring seems like a small thing, it’s a big deal. That’s why it’s important to choose a slip ring that’s appropriate for your turbine design. When considering slip ring manufacturers, here’s a great question to ask: “Is the slip ring engineered specifically for wind applications?”

A quality, custom-engineered slip ring for wind applications can reduce cost and improve performance, by ensuring unwanted design features aren’t included, while critical design features are. A custom design also requires less maintenance, incurs less downtime, and is more efficient. In other words, it’s built to last.

When looking at the effectiveness of a wind turbine slip ring, manufacturers take into consideration a variety of factors. The key factors include maintenance frequency, maintenance downtime and power transfer.

Factor #1: Maintenance Frequency

You might think a longer life requires more maintenance. Actually, if you choose a quality slip ring, the opposite is true. A slip ring should be designed to last the entire 20-year life of a wind turbine. It should also allow for 100-200 million revolutions before brush replacement.

Some questions to ask when vetting slip ring manufacturers:

- Are your brushes robust and solid enough to be resistant to power surges?

- If a brush gets damaged, do I need to replace the whole block or just the individual brush?

- Is the assembly robust enough to handle vibrations and environmental conditions present in a wind turbine?

- Will the slip ring support the communication protocol passing through the communication channels?

Slip Rings can be designed with maintenance in mind. The more that is known about the specific turbine conditions, the better the slip ring can be designed to survive a 20-year lifetime. A quality slip ring will save time and money on both parts and labor.

Factor #2: Maintenance Downtime

Quality slip rings help you get your turbine back up and running faster.

For example, with quality slip rings, you should only need to replace a single brush—not an entire assembly. With lesser quality slip rings, you can waste time replacing working brushes and waste money on extra materials.

Also, quality slip rings should only require five minutes of maintenance per year, and sometimes, annual maintenance isn’t even necessary.

Some questions to ask when comparing slip rings:

- How long does it take to replace each brush?

- Is annual maintenance required? If so, how much?

- Do your slip rings have built-in, lifelong lubrication?

With the right slip ring, you’ll reduce downtime, and increase productivity and profits.

Factor #3: Power Transfer

There was a time when slip rings had a reputation for power loss and limited capacity. That’s no longer true. Today, quality slip rings are extremely efficient and can transfer higher wattage with decreasing power loss.

Additional questions to ask slip ring manufacturers:

- What is the maximum voltage and ampacity the slip ring was designed for? This will relate to the power (in kilowatts) the slip ring can safely handle.

- What is the slip ring’s power factor (efficiency)?

The slip ring should have more than 99 percent power factor. Without a near-perfect power factor, the slip ring will hinder the electrical system and, more importantly, the power lost is converted to heat that will damage the slip ring system. There are a lot of factors, specifically contact size and design, that can affect power transfer capacity and power loss. Choosing slip rings custom-designed for the specific wind turbine application can help you ensure proper capability and function.

A Critical Component

Just as in any electrical system, every component has its importance. All these components need to work in series with another for the greater system to function. So yes, slip rings are just a small part of the overall wind turbine, yet their mission is critical to its uptime, efficiency, and profitability. All things considered, small slip rings are a really big deal.

Read full article here.