When United Equipment Accessories (UEA) begins the design process of a new custom slip ring, UEA’s engineers review the environment where the slip ring will be used to understand better what will be needed for the slip ring design. Recently, UEA received a request to design a slip ring for an industrial oven. The slip ring would need to withstand 450 °F-500 °F with a continuous rotational speed of 12-15 RPM. This high-temperature slip ring project was an excellent challenge for UEA because it allowed UEA to find a creative solution for our customers and grow UEA’s knowledge of a new market.

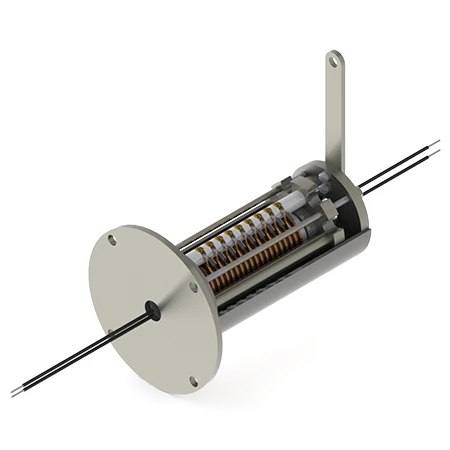

Customized High-Temperature Slip Ring Specifications:

- Rated to 450 °F-500 °F (232 °C-260 °C)

- Small diameter

- Thermocouples

- 18 circuits

- High-temperature insulators

- High-temperature solder

- High-temperature bearings

- Stainless steel housing

Using existing designs and higher-rated materials enabled UEA to succeed in this project. Knowing that the materials will expand and contract, our engineering team was able to specify and design the necessary components to make this slip ring possible for a high heat environment. In addition to sourcing high-temperature rated component materials, UEA also identified the appropriate wire, solder, and tolerances for machining to ensure the slip ring would work in this extreme environment. UEA used ceramics and then hardened them by kiln firing, ensuring these parts could withstand such demanding heat ranges.

This new design and materials allow United Equipment Accessories to continue to solve problems for our customers with compact and unique designs. Contact us today to learn more about UEA’s high-temperature slip ring solutions.