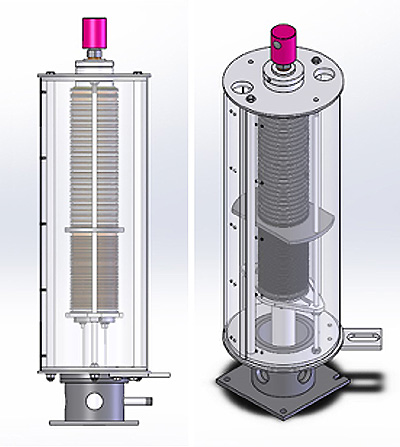

A new 62-circuit electrical slip ring has made its way through United Equipment Accessories. This S15C series slip ring with mounting tube assembly was designed to be mounted upright in a dual boom stretch wrapper application. Each boom section requires 12 circuits for power, 18 circuits for signal and 1 circuit for ground. The customer also requires an air-line to pass through the slip ring which required a special mounting tube and a ¼” pneumatic air swivel.

The S15C series slip ring is in our 1.50” bore slip ring group and is made up of aluminum end castings and a wrap aluminum cover. The top plate includes two holes for brush harness exits and the mounting tube includes two holes for center harness exits. Each exit hole, stator and rotor, requires identical 8’ cable bundles for each boom section on the machine. The mounting tube also includes a pipe nipple and pneumatic air swivel for customer air hookups. Due to the height of the core of the slip ring and the amount of brushes, a center bearing is added for support. The bottom end plate includes a Nylatron bearing and custom, zinc-plated, torque bracket for customer retention. The top plate also includes a nylon bearing and shaft seal for extra sealing. For extra structural strength, steel support tubes have been added in between the end plates.

United Equipment Accessories continues to strive to make sure that each customer gets the features that they want for their slip ring assembly! For more information about slip rings, visit our slip ring product page.