When designing a new slip ring for our customers, we work with the customer to determine the best connection type for the slip ring’s application. Each connection style has advantages and disadvantages given the slip ring’s application, ease of connection to application, and amperage rating. We will review the connection options available for both the slip ring brushes and slip ring core.

Connection to the Slip Ring Brushes

When connecting to the brushes, knife disconnects are one of our most used forms of connection. This connection is made from knives that are crimped onto both the brush and the brush harness. These knives get interlocked together and are then covered with a vinyl sleeve or heat shrink. If a vinyl sleeve is used, a zip tie is placed directly next to the sleeving to prevent it from slipping off the connection and exposing the knives. This is an excellent form of connection because it is easily replaceable.

Butt splices are also a very common form of connection when connecting to the brushes. The butt splice gets crimped to the brush on one side and the harness on the other. It is then covered with heat shrink for insulating purposes.

We also provide an option for the customer to connect to terminal blocks on the brush side. In this option, UEA uses a brush lead set to wire the brushes directly to terminal blocks that are mounted on the base casting. This gives the customer an easy way to connect and disconnect from the slip ring.

The final option for hooking up to the brushes is by using either eyelets or lugs. If the customer’s application has a high enough amperage rating, UEA will supply brushes with bus bars. These bus bars contain either a cap screw to land an eyelet on or a lug to connect the brush harness to.

Connection to the Slip Ring Core

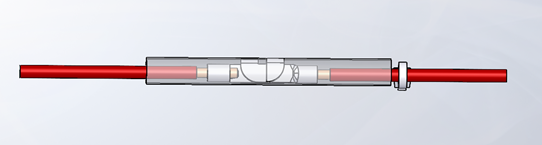

When hooking up to the core of the slip ring, top crimp connections are our most common form of connection type. The UEA assembly team strips the wire jacket on both the core leads and the center harness for this connection. Next, they fit both stripped ends of the wire into the wire joint and crimp it on.

On non-prewired slip rings, we supply set screw connectors, so the customer can make these connections in the field without needing to use a crimping tool.

UEA also has a method of connecting to the core with extended core leads. These leads are soldered directly onto the rings in the core, so no extra connection point is necessary.

Installing the core leads into terminal blocks is another form of connection that can be used. The terminal blocks are mounted on top of the core using extended core studs and a mounting plate.

The final form of connection to the core is by bus bars. As previously stated, bus bars contain either a cap screw to land an eyelet on or a lug to connect the center harness to. The bus bars are then covered with heat shrink for insulation purposes.

When hooking up the slip ring to your application, the sky is the limit for connection types. UEA can supply harnesses with terminals, eyelets, butt splices, and all sorts of connectors on the customer end. We stock over 350 different styles of terminals. Curious what connection would be best for your application? Contact us to discuss options with our engineers!