Rotary unions are key in transferring fluids and gases between stationary and rotating parts, ensuring seamless operations in various industries. With so many types and specifications available, navigating through the options can feel overwhelming. This guide will simplify the selection process, highlighting key factors like pressure, temperature, and media type, to help you make the right choice.

1. Understand Rotary Union Application Requirements

- Type of Media: Identify the fluid or gas that will be transferred. Rotary unions are designed for different types of media, including water, oil, air, steam, and chemicals. Matching the right union to the media helps maintain efficient transfer and prevents issues like corrosion or leakage.

- Application Environment: The environment in which the rotary union will operate plays a significant role in determining the right choice. Factors like exposure to corrosive substances, extreme temperatures, and cleanliness requirements affect the materials and design best suited for the job.

2. Rotary Union Pressure and Temperature Ratings

- Pressure Rating: Verify that the rotary union can handle the maximum operating pressure of your system. Rotary unions come in a variety of pressure ratings, so selecting the appropriate one helps prevent issues like leakage or premature failure.

- Temperature Rating: Different applications require unions that can handle various temperature ranges. For example, high-temperature environments might require unions made from specialized materials to prevent degradation of seals or other parts.

3. Type of Sealing Mechanism

The sealing mechanism is a key aspect of any rotary union, as it prevents leaks and keeps the system operating smoothly. When selecting a rotary union, consider the materials and types of seals:

- Seals and Compatibility: The choice of seal material—whether elastomers, PTFE, or metals—should be based on the type of media being transferred. Each material offers distinct levels of chemical resistance, durability, and temperature tolerance. Choosing the right seal minimizes maintenance and extends the lifespan of the union.

4. Rotary Union Design and Rotational Speed

The design of the rotary union should meet your system’s specific needs. Here are some key considerations:

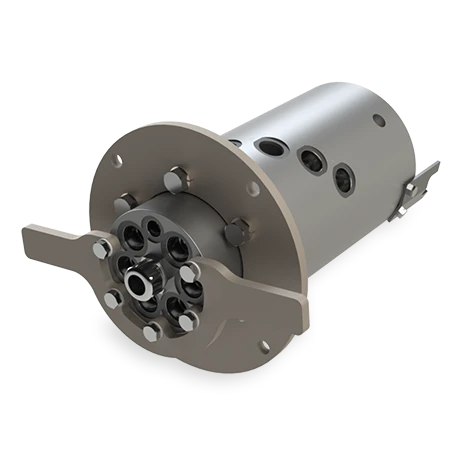

- Single-Passage vs. Multi-Passage: Single-passage rotary unions are ideal for transferring one type of fluid or gas. For more complex systems, multi-passage rotary unions allow the transfer of multiple fluids simultaneously, providing flexibility and efficiency in diverse applications.

- Size and Configuration: Make sure the rotary union’s size and configuration fit within your equipment’s space constraints and installation requirements. Proper alignment and mounting are important for smooth operations.

- Rotation Speed: The rotational speed at which the union will operate is another important factor. Higher speeds can wear out seals and bearings more quickly, so select a union designed to handle the specific RPMs of your machinery.

5. Material Selection

Material choice directly impacts the durability and performance of the rotary union:

- Material Durability: Choose materials that can endure the operational stresses of your application. Common materials like steel, ductile iron, and specialized alloys are often used to handle harsh environments.

- Corrosion Resistance: In environments with corrosive substances, such as chemicals or seawater, choosing materials with high corrosion resistance, like stainless steel, will add to long-term reliability.

Why Choosing the Right Rotary Union Matters

Making the correct rotary union selection is important so your equipment runs efficiently, reducing downtime, and extending the life of your machinery. Factors such as pressure and temperature ratings, sealing mechanisms, design specifications, and material choice all contribute to the union’s overall performance. Whether your application involves high-pressure hydraulic systems, forestry equipment, or rugged construction machinery, selecting the right rotary union will help improve operations and reduce maintenance.

United Equipment Accessories (UEA) offers expert guidance in helping you choose the right rotary union for your unique application. With decades of engineering experience, UEA’s team can recommend solutions tailored to your operational needs. Contact UEA today to learn more about our rotary unions and other precision components.

-Vinay Patil, Application Design Engineer