United Equipment Accessories designed and manufactured a large custom slip ring that will be used in the center of a wastewater treatment tank. The slip ring will sit in the middle of a 30-meter diameter tank and will be exposed to not only outdoor elements but also the wet environment of the tank.

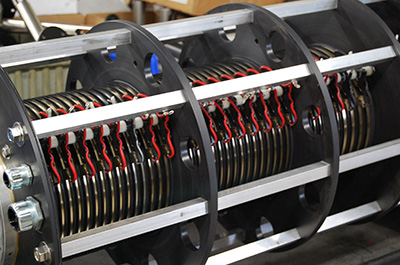

To meet the needs of the customer’s project, we created a 120mm thru-bore design that would rest on a custom-engineered mounting tube that would be mounted upright in the middle of the tank. Nine custom machined parts were created including the drive tube, insulators, bearing plates and brackets. A wrap-around aluminum cover was used to allow for the thru-bore design.

To ensure the slip ring could withstand the environmental conditions of this application, the slip ring was sealed on the top and sides to prevent water from entering while the bottom of the assembly allowed for water to exit and dry if any moisture entered the assembly. Corrosion inhibiting parts were used throughout the assembly.

The slip ring contained 44 circuits to meet the multiple power requirements as well many signal circuits for the application. Due to the large diameter of the wastewater treatment tank and the placement of the slip ring at the middle of the tank, 100-foot-long cables were needed to reach past the sidewall of the tank. This totaled over 1,600 feet of cable that was needed for this assembly.

When a company brings a challenge forward, we work to find a solution to meet their need. For this unique application, we were able to design a custom slip ring solution for the customer that met their specifications. Learn more about our custom slip ring solutions for your next project.