Custom Slip Rings

UEA designs and builds custom slip rings that move power and data through continuous rotation. From compact capsules to large through-bore assemblies, we size the circuits, contact system, and sealing to your duty cycle and environment.

Applications range from construction and agriculture to marine, wind, robotics, medical equipment, and factory automation. We support Ethernet/CAN, HD video, and mixed signals, with brush/track metallurgy and IP ratings selected for your application.

Why Go Custom with UEA

- Built around your mounting pattern

- Power + signal layouts with low electrical noise

- Stainless and coated housings for corrosion resistance

- IP-rated sealing for dust, spray, or washdown

- Designed for the duty cycle and RPM you specify

Design Options & Capabilities

- Form factor: through-bore and custom bore sizes

- Circuits: high-current power, low-level signals, mixed layouts

- Protocols: Ethernet, CAN, HD-SDI/video, encoder feedback

- Contact system: brush/track materials matched to current density

- Sealing: IP options for outdoor, washdown, or marine exposure

- Integration: shaft size/bore, flange pattern, wiring, strain relief

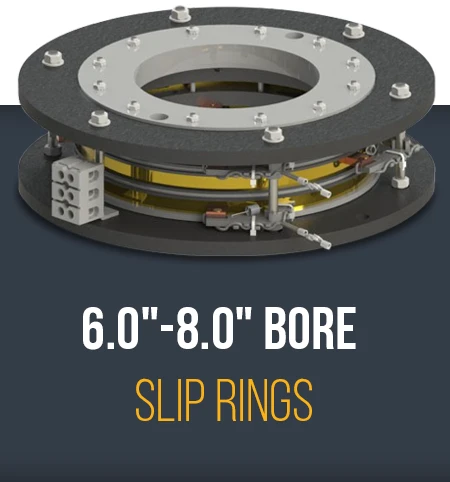

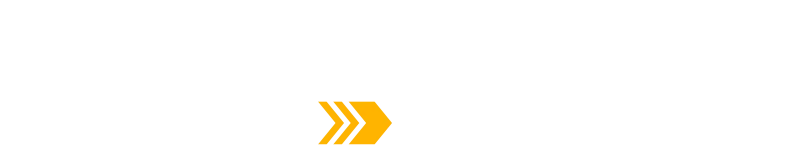

Slip Ring Examples – Built to Your Specs

Choose by bore size, then tell us your circuits, voltage/current, RPM, and environment.

High-performance compact slip rings.

- For space-limited, high-performance applications, these are commonly used in robotics, CCTV cameras, and are ideal for subsea and marine environments.

Our most popular and versatile unit.

- The design flexibility allows us to employ a modular concept in its construction, which allows us to meet specific requirements for amperage and voltage combinations.

Used in large-scale applications.

- Utilized in heavy machinery within the medical industry and construction sector, maintains steady performance, continuous power and data transfer.

Precision in industrial automation.

- Large Bore Slip Rings enable precise control in rotary tables for precision machining and automated assembly lines. This capability is important for precise control.

Maximizing equipment efficiency.

- Benefiting equipment like storage silos, waste treatment facilities, and pedestal cranes, offering superior solutions for large-scale applications.

The FAQ’s

Commonly Asked Questions about our Custom Slip Rings

Circuit count and types (power vs. signal), amperage/voltage, data protocols (e.g., Ethernet/CAN), RPM/duty cycle, bore/size constraints, temperature and sealing needs.

Yes. Mixed power/signal designs are common. Your engineering team will match brushes, rings, filtering, and shielding to the protocols.

Start with the required center passage (shaft, hoses, cables) and envelope limits. Then pick the closest bore class and finalize circuits/ratings.

At UEA, we believe that every query is the doorway to innovation. We are committed to collaborating effectively. Reach out with your questions and let’s get started!